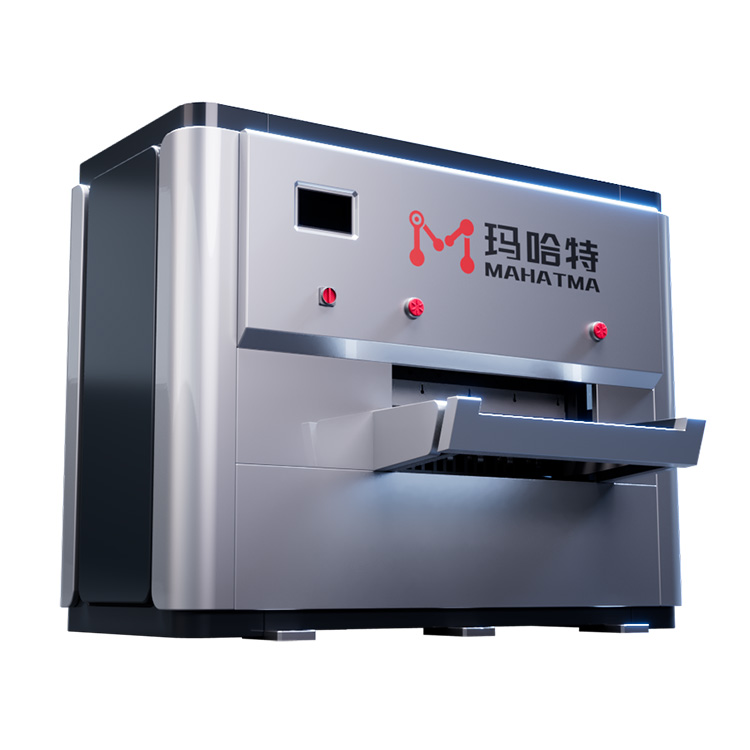

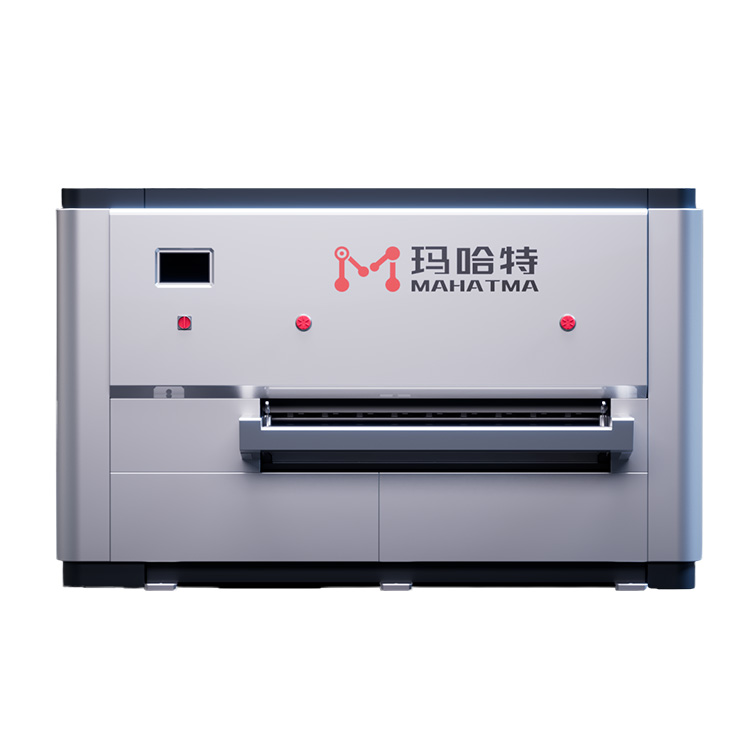

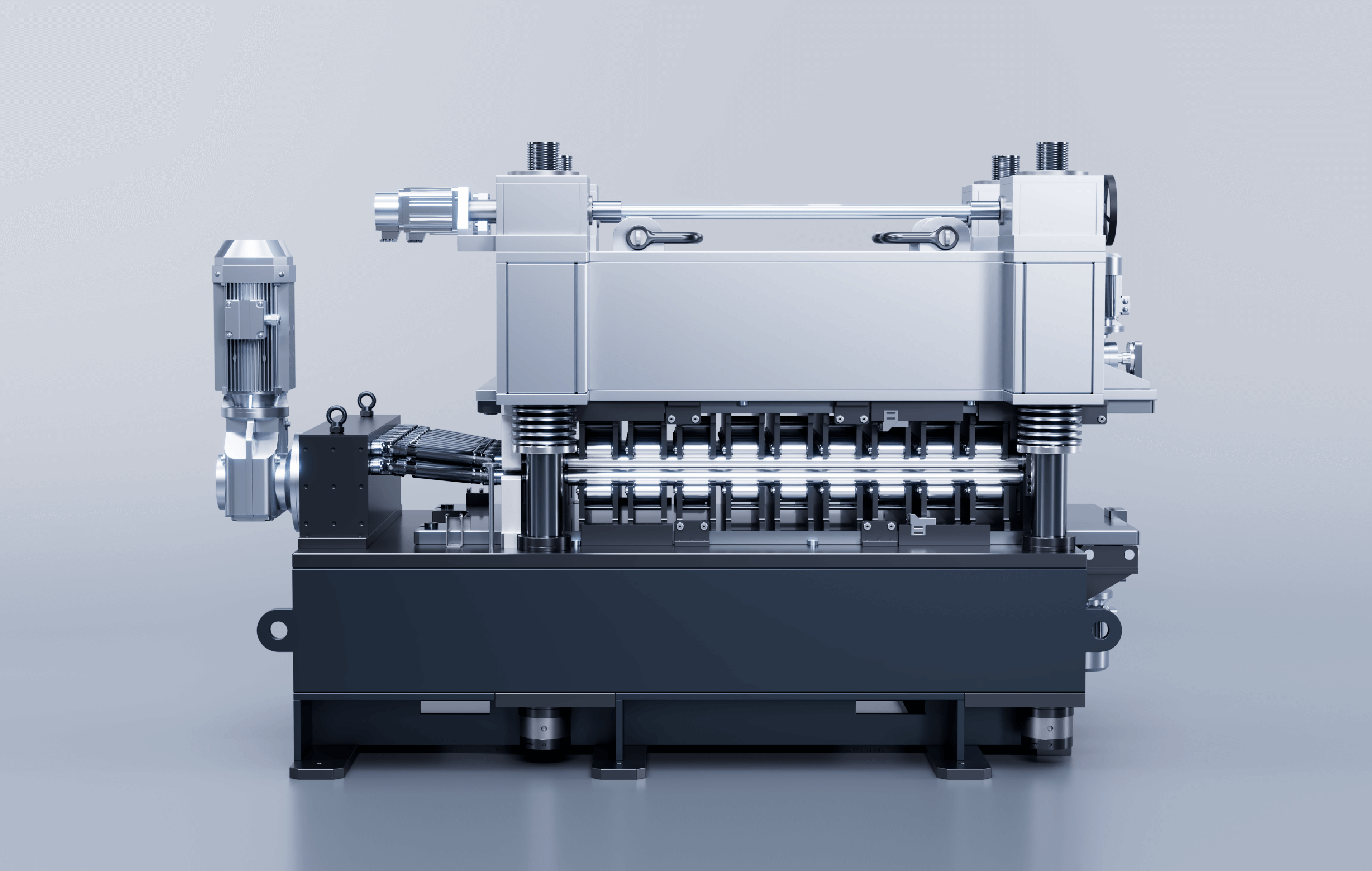

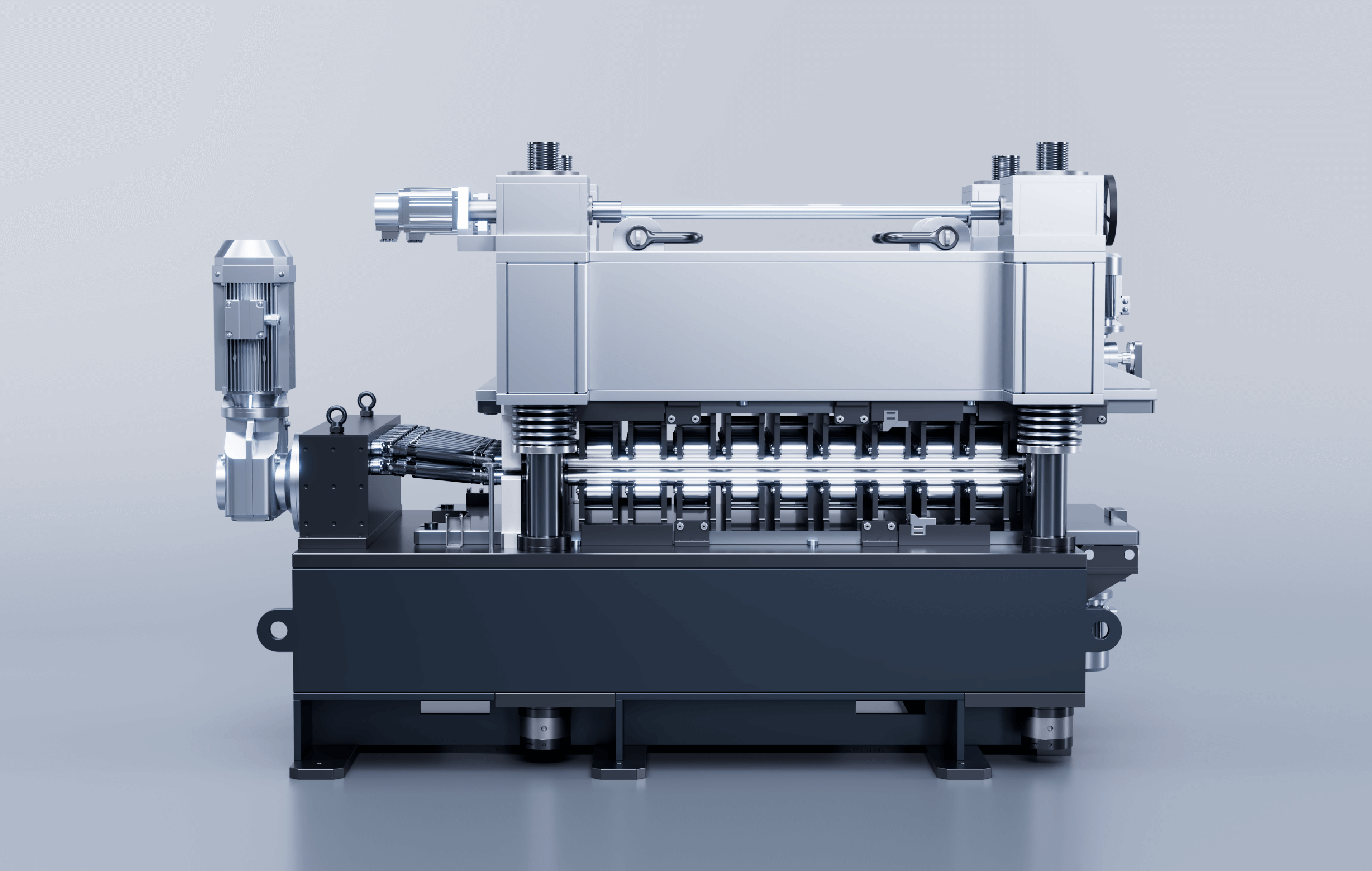

Ang makinang ito ay gumagamit ng Siemens PLC controller at kinokontrol ng Siemens frequency converter para sa bilis ng pagpapatakbo. Ang lahat ng paggalaw ng makina ay sentral na kinokontrol ng operating platform, na may touchscreen na human-machine interface display screen at isang simple at madaling maunawaan na operating panel. Naka-install ang mga emergency switch sa apat na prominenteng posisyon sa inlet at outlet ng makina para matiyak ang ligtas na operasyon! At nilagyan ng isang digital na display upang ipakita ang displacement, ang operasyon ay napaka-simple at mabilis. Sa loob lamang ng ilang segundo, maaaring i-level ang high-precision at kumplikadong mga bahagi ng hardware na karaniwang nangangailangan ng pangmatagalang manual leveling.

Mga Tampok ng Produkto

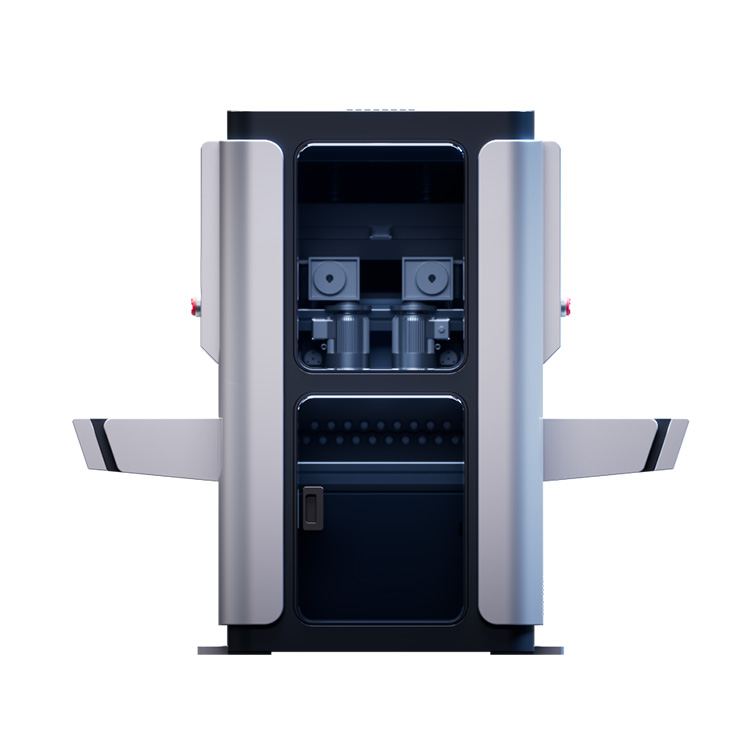

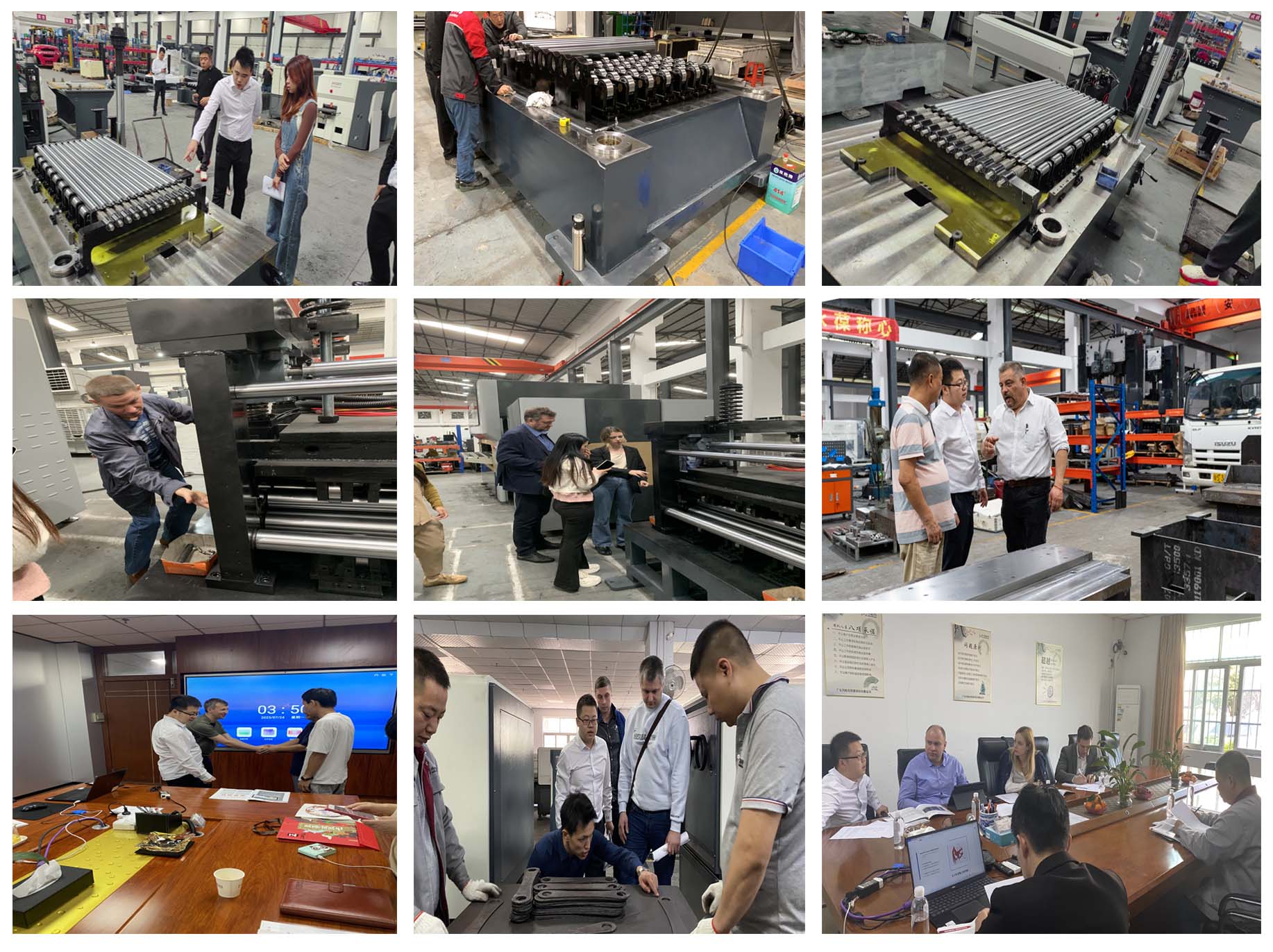

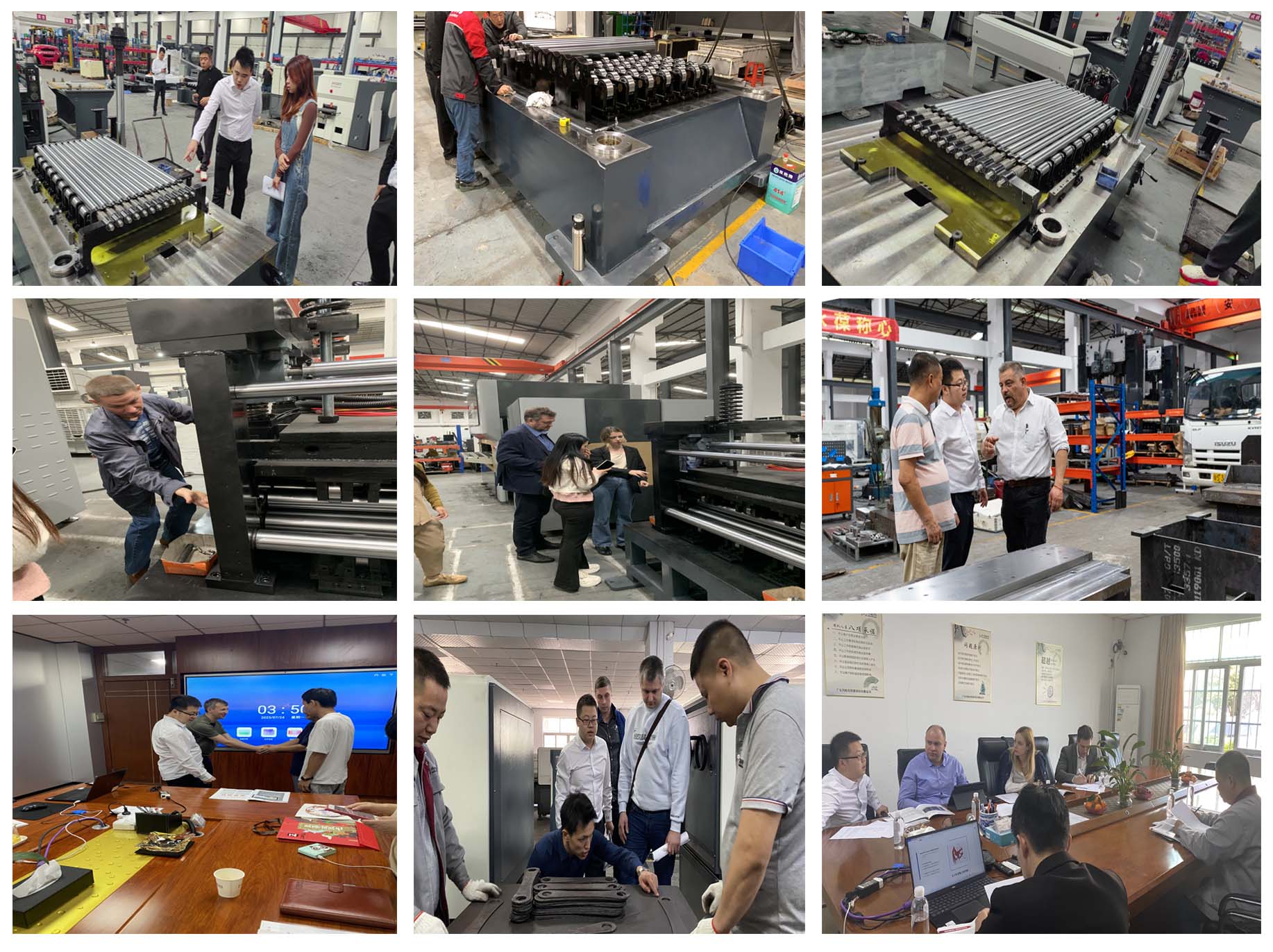

★ Ang roller ay maaaring ganap na awtomatikong makuha (maginhawa para sa paglilinis ng roller)

★ Awtomatikong pagkalkula ng dami (maaaring ikonekta sa iba't ibang MRP at ERP system para sa kontrol, awtomatikong setting at pagsubaybay sa oras ng pagsisimula ng kagamitan, epektibong oras ng pagtatrabaho, at awtomatikong pagbibilang ng mga naprosesong bahagi)

★ Buong suporta (ang buong roller ay ganap na sinusuportahan, na may malakas na puwersa ng istruktura)

★ Awtomatikong pag-andar ng pagsubaybay (maginhawa para sa pagsubaybay sa kagamitan at katayuan ng produksyon anumang oras, maginhawa para sa pagkumpuni at pagpapanatili)

★ Malapad na support shaft (pinapabuti ang operating rigidity ng leveling roller at binabawasan ang indentation sa mas malaking hanay)

★ Remote control function (para sa mga customer na nasa malalayong lugar, matutulungan ng aming mga inhinyero ang mga customer na malutas ang mga problema gaya ng hindi kakayahang ayusin ang mga makina o kagamitan na hindi gumagana anumang oras)

★ Proteksyon ng optoelectronic (upang maiwasan ang mga hindi kinakailangang panganib sa kaligtasan na dulot ng mga tauhan o workpiece na nakapasok sa kagamitan nang hindi sinasadya)

★ BMW na pintura (gamit ang high-end na BMW baking paint, ang buong makina ay stable, high-end, at maluho)

★ Awtomatikong flatness detection (awtomatikong pag-scan sa katumpakan ng detection) (opsyonal)

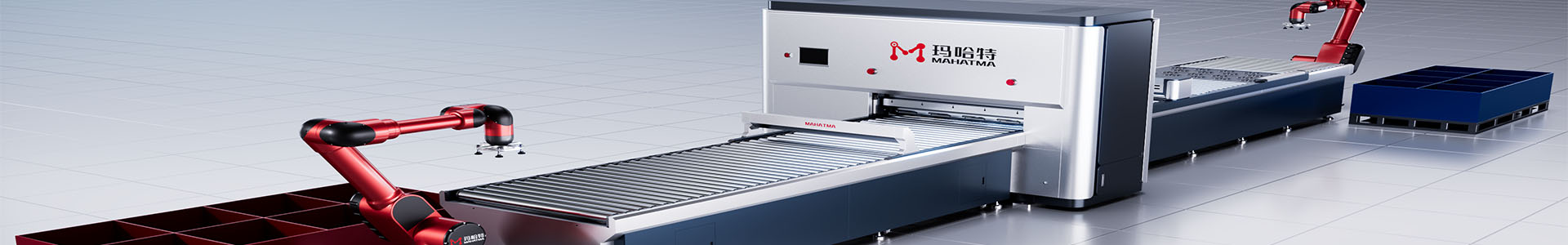

★ Unmanned at ganap na awtomatikong pagsasaayos ng buong linya (opsyonal)

1. Matalinong operating system

Bagong estilo, malakas na dynamic na pagganap at katatagan, pagpapabuti ng software operation smoothness; Pinagsamang mabilis na intelligent leveling mode;

2. MHTP series high-precision leveling machine

Mga independiyenteng karapatan sa intelektwal na ari-arian, maramihang patented na teknolohiya, napakataas na kahusayan sa leveling, matalinong kontrol;

3. Lahat ng machine tool self-lubricating system

Mataas na katalinuhan, mataas na integrasyon, walang maintenance, isang pag-click na setting ng mababang presyon ng langis alarma, walang oil shutdown, upang maiwasan ang machine wear sanhi ng pagkaantala ng pagpapadulas;

4. Remote cloud control system

Maaaring makamit ang malayuang pagsubaybay sa katayuan ng pagpapatakbo ng kagamitan, pagtatanong ng kasalanan, pagsusuri ng kasalanan, atbp., at real-time na pagsubaybay sa ulap ng kagamitan;

5. Independently developed gearbox

Gear universal joint transmission, faster acceleration and speed, better rigidity and impact resistance;

6. Hollow structure machine tool

The main body of the machine tool has no heating area and is permanently used without thermal deformation. The machine body is stable and reliable, ensuring long-term stability of leveling accuracy.

| Servo CNC Leveling Machine Parameters |

| Model | MHTW50 | MHTW60 | MHTW80 | MHTW100 |

| Leveled Width | 0-1600mm | 0-1600mm | 0-1600mm | 0-1600mm |

| Roller Diameter | φ50 | φ60 | φ80 | φ100 |

| Roller Number | 23 | 21 | 19 | 19 |

| Rated Thickness(Q235) | 0.8-4.0mm | 1.0-6.0mm | 2.0-8.0mm | 3.0-12.0mm |

| Maximum Thickness(Q235) | 8.0mm | 12.0mm | 16.0mm | 20.0mm |

| Shortest Workpiece | 90mm | 100mm | 130mm | 160mm |

| Leveling Speed | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min |

| Voltage | AC three-phase 380VAC | AC three-phase 380VAC | AC three-phase 380VAC | AC three-phase 380VAC |

Sheet metal leveling machines are an essential tool for those involved in sheet metal processing. These machines are designed to flatten and level sheet metal, which is commonly used in a range of industries, including automotive, construction, and manufacturing. Sheet metal leveling machines are a valuable asset for any business involved in sheet metal processing, as they can improve the accuracy and efficiency of the production process.

Sheet metal leveling machines are used to flatten and straighten sheet metal that may be warped or bent due to the manufacturing process or transportation. The machines use a series of rollers to apply pressure to the sheet metal, which helps to remove any kinks or bends in the material. The rollers are positioned at precise intervals along the length of the machine, which ensures that the metal is flattened and leveled evenly and accurately.

One of the key benefits of using a sheet metal leveling machine is that it can improve the quality of the finished product. Sheet metal that has been leveled using a machine is much more likely to meet the required specifications for size and shape. This can help to reduce the number of defective parts produced, which can save manufacturers time and money.

Another advantage of using a sheet metal leveling machine is that it can improve the efficiency of the production process. The machines are capable of leveling large volumes of sheet metal in a relatively short amount of time. This can help to increase the output of the manufacturing process, which can lead to higher profits for the manufacturer.

Sheet metal leveling machines are also very versatile machines. They can be used to level a wide range of different sheet metal thicknesses and sizes, including aluminum, copper, and steel. This makes them a valuable asset for manufacturers who work with a variety of different materials.

In addition to their versatility, sheet metal leveling machines are also very easy to operate. They require minimal training to use, and most models come with user-friendly controls that allow operators to adjust the tension and speed of the rollers. This makes it easy for manufacturers to incorporate these machines into their existing production processes.

Overall, sheet metal leveling machines are an essential piece of equipment for manufacturers who process sheet metal. They can improve the quality and efficiency of the production process, and they are capable of leveling a wide range of different sheet metal thicknesses and sizes. Whether you are a small business or a large manufacturer, investing in a sheet metal leveling machine can help you to produce high-quality parts that meet the required specifications.